The QIDI Tech X-MAX 3 is a high-speed upgrade of the X-MAX model with a larger build volume and a lot of useful improvements aimed at high performance and industrial-grade print quality. Like the original X-MAX, the X-MAX 3 comes assembled and ready to work within 10 minutes after unboxing. The machine is fully enclosed and now boasts an actively heated build chamber with an independent heater and a maximum temperature of 65 °C, which ensures reliable printing with high-performance thermoplastics. The chamber is equipped with a circulation fan with an active carbon air filter for better printing results and safe environment.

Based on the CoreXY kinematics and equipped with Trinamic TMC2209 silent stepper drivers, the X-MAX 3 can reach a lightning-fast print speed of 600 mm/s and acceleration of 20000 mm/s² yet working quietly. The resonance compensation function allows reducing the impact of vibrations, ensuring high print quality without visible artifacts. Use of carbon rods on the X-axis and a more lightweight extruder with a 9.5:1 gear ratio reduces the weight of the whole structure making for smoother and faster movements. The X-MAX 3 features automatic 16-point bed leveling with a BLTouch sensor to ensure good first layer adhesion and prevent part deformation.

Print quality

The QIDI Tech X-MAX 3 features a direct drive extruder with a maximum flow rate of 35 mm³/s. It comes standard with two high-temperature hotends that can heat up to 350 °C, allowing printing with most engineering-grade thermoplastics. The copper alloy nozzle provides excellent thermal conductivity and suits for processing common filaments, while the durable hardened steel nozzle is ideal for abrasive materials.

A standard 0.4 mm nozzle can be replaced with optional 0.2, 0.6, or 0.8 mm nozzles. With a minimum layer height of 50 microns, the X-MAX 3 produces accurate models with smooth surface finish. The print bed heats up to 120 °C and features a magnetic flexible build plate that ensures good adhesion and easy print removal.

Materials

The X-MAX 3 is compatible with a wide range of proprietary and third-party filaments. Its high-temp extruder and fully enclosed heated build chamber allow handling high-performance materials such as Nylon, PC, fiber-reinforced composites, and others, alongside common PLA, ABS, ASA, PETG, and flexibles.

Build volume

Compared to its predecessor, the X-MAX 3 sports a more spacious build chamber of 325 x 325 x 325 mm, allowing for printing fairly large parts or batches of smaller models.

Printer controls and software

The X-MAX 3 boasts a 5" color touchscreen with 800 x 480 resolution, which is easy to navigate. The machine has various connectivity options including Wi-Fi, Ethernet, and USB.

Based on the popular Cura slicer, the QIDI Print software has normal and expert modes to provide maximum flexibility both for beginners and experienced users. It runs on Windows, macOS, and Linux. The printer is also compatible with Cura, Simplify3D, or PrusaSlicer.

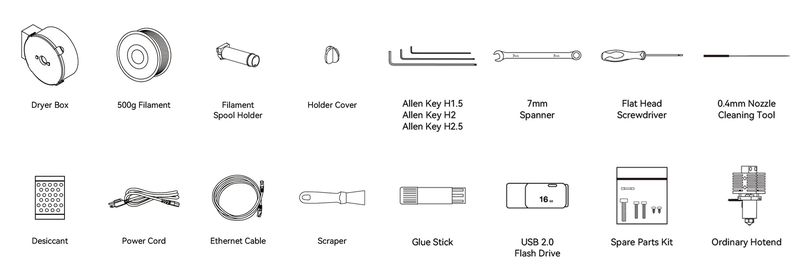

What’s in the box

- QIDI Tech X-MAX 3 3D printer

- Two hotends

- Filament dryer box

- Spool of filament

- Filament spool holder

- Tool set

- 0.4 mm nozzle cleaning tool

- Desiccant

- Power cord

- Ethernet cable

- Scraper

- Glue stick

- USB 2.0 stick

- Spare parts kit

For some items, package content may change. In case of any questions, please get in touch.

Look and feel

The QIDI Tech X-MAX 3 3D printer is available in black and white. Its stylish look and enclosed design make it ideal for any production environment.

The machine dimensions are 21.8 x 21.8 x 23.7 in (553 x 553 x 601 mm). It weighs 54 lb (24.5 kg).